Implementing LEAN. Stability, Leadership and PDCA

In this new post I would like to talk about how to start implementing lean… because, I imagine, that the ones who have started implementing it, may have used these two options:

- Option 1: Doing the typical diagnose, which is not bad. (In fact, there is nothing better than going to the “doctor” to know what´s wrong with you and how to start acting)…

- Option 2: With the typical 5 S´s… or any other specific project, even a successful one, that has made you “receive your investment in time”… which is also not bad.

But Does all this guarantee the success of Lean implementation?

And the answer, unfortunately, is no…

Some of you will wonder How can we start implementing lean if we don´t have time? And you are right…

There are three concepts that I would like to introduce you, as a key factors to start implementing lean:

As a step 0, start step by step, with a concrete area, and if it works people will copy it, you do not need to “sell it”…

- Guarantee Stability

- Lean Leadership

- Problem Solving to all levels

Balance and Lean

After step zero, what you have to do is try to have STABILITY. It is nearly impossible to implement lean sustainable over time, if the environment is not stable… without stability it is very difficult to improve.

How do we try to have stability? How could we try not to be so busy, everyone, every day?

There are also three key factors to achieve stability:

- Appropriate Information

- Capacity for Problem Solving

- Standard Process

1 .- Stability and appropriate Information

We have to have the appropriate information to be capable, at all levels, of answering quickly the next questions:

- How did we do yesterday? or, even How are we doing it now?

- What´s today´s plan? And How is our plan working now?

- How are our pending actions?

- Anything to note down for today or tomorrow?

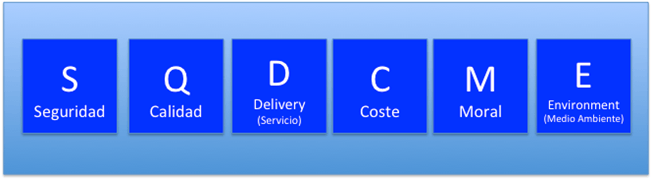

What we talk about is a Management Control System (day by day, shift by shift, even hour by hour …) based on equipment and key indicators KPI´S.

The first one is inalienable, safety of staff, How could we demand anything if we do not provide security?

Having the appropriate information, we will be able to prioritize and differentiate between what is URGENT or IMPORTANT, to focus our effort.

2 .- Stability and Problem Solving

Once focused on our efforts, we have to develop our teamwork to be able to solve problems … FOREVER!!

If today we are very busy, but we can solve an important problem from the root, maybe tomorrow we will be a little bit less busy… and then, another one, and another… and maybe we will start to be more stable.

3.- Stability and Standardisation

When we have achieved some stability, we can start thinking about work standards. Which is the best way of doing a concrete operation?

Because we need a standard, it is not right that everyone does it their way or each shift does it their way…

Lean and Liderazgo Lean

This is, probably, the most important part and the one that managers and directors delegate the most.

“My team will do it. I trust them completely”

“Is this not a Continuous Improvement task?”

“I am too busy; don’t have time for this”

This is something that you can´t delegate. This is a way to make lean fail.

If you are not going to get involved, DO NOT START.

Managers have to get involved in the day to day, in “go and see” (not just walk over the plant)… “go and see” is not just “go so that they can see you”, it is a nice opportunity to listen, argue, understand problems and try to fix improvements and listening to your people “from peer to peer”

We have already talked about standards, so let us define a standard for each manager and director, for them to “go and see”, to evaluate their teams, to understand how standards work, to follow indicators and goals.

Bad news, managers changed their job… or Maybe it is not bad news after all…

Another important issue in lean leadership is that managers and directors have to have their duties clear. They need to be trained and re-trained, defining those new roles:

- Members of the core team

- Team leaders

- Managers or area managers

- Plant managers

Problem Solving (PDCA) and Lean

Problem solving must be a habit in each level of the company.

Problems must be something we want to face, rather than something we want to hide or pass to someone else…

When I say all levels, I mean from General Director or President, to worker.

If in top levels of the company, we do not practise PDCA to solve root problems. How can we demand for the rest of the people to do it?

Leadership must be “Lead by example”

Comments are closed.